ScanForce provided the following February 2022 update about their Sage 100 Warehouse Management solution. This includes new products as well as demonstrations and webinars. Many of these webinars are recorded and will be provided to you after the meeting is held.

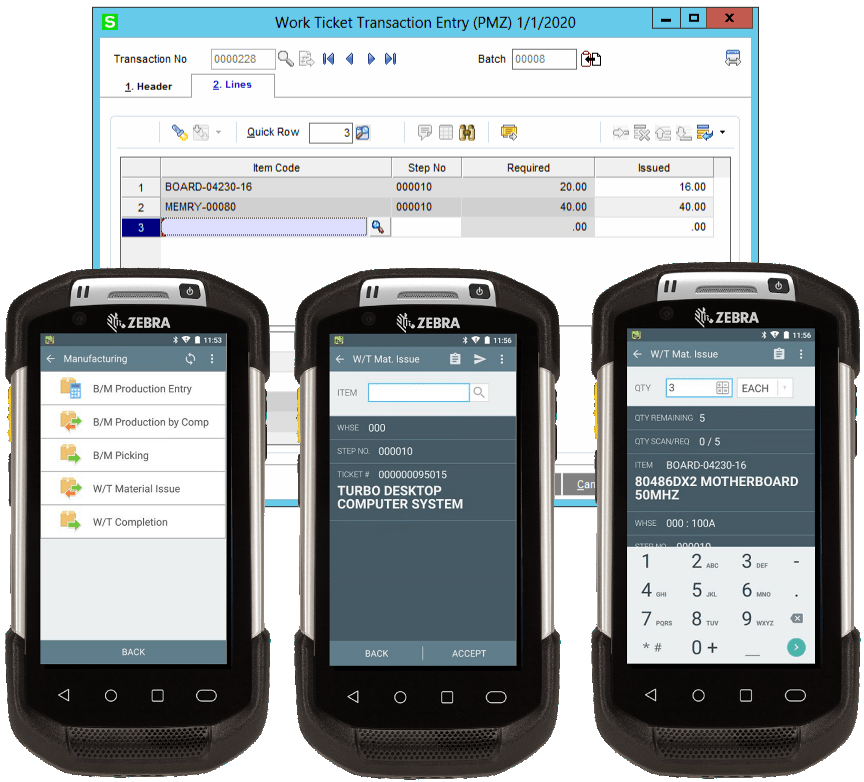

Customers who use ScanForce typically are also using mobile bar code scanners so their warehouse employees can pick, pack and ship while completely untethered from a computer.

ScanForce also offers a multi-bin option to allow for inventory items to be assigned into more than one bin. This enhancement also allows for restrictions by bin which can be useful for inspections or allocating of inventory to a specific use such as customer or manufacturing.

Sage 100 Webinar: The 2022 Warehouse: Doing More with Less

Every day we talk to businesses who are struggling to retain sufficient staffing for their warehouse operations. With no end in sight to the current labor shortages, businesses need to find ways to work smarter, not harder, in the warehouse. Join us to learn about tools and workflows for Sage 100 users that can facilitate the movement and tracking of inventory through barcode scanning technology, reducing the need for human intervention and keeping your inventory flowing.

We’ll cover:

- Hidden ways that being short-staffed hinders growth

- The basics of Warehouse Management Systems (WMS)

- How using a WMS fast tracks employee onboarding

- New workflow automation tools such as Pallet Tracking, Make To Order, and our new enhanced Sales Order Wave Pick/Ship

Tue, Feb 1, 2022 1:00 PM – 1:30 PM EST – Register Here

ScanForce Feature/Product Release Schedule – 2022

Make to Order – create a Production Mgmt Work Ticket directly from a Sales Order – released Q2 2021

Contact ScanForce for more information or to schedule a demo.

Labor Mgmt Console – view and edit Production Mgmt Labor transactions before committing to Sage 100 – released Q2 2021. Read more about Manufacturing Labor Tracking

Enhanced Sales Order Wave Pick/Ship Selection – added to our ScanForce Management Console, sales orders can be selected to be added to a wave of orders to be efficiently picked or shipped together. Orders can be individually selected or bulk selected based on filtering by certain fields. – Released Q3 2021

Support for Sage 2022 – within days of Sage’s release, expected sometime in March.

Container Receipt Management Enhancement for Sage 100

Use Container Receipt Management when you need to receive a shipment on the books for accounting purposes, but the items haven’t been physically received yet and are therefore not available for sale. For example, when a shipment is in transit, perhaps stuck on the water, and you’ve taken ownership of the items, but they haven’t been physically received.

Recent Case Study – All Seasonings Ingredients Achieves Growth After Transitioning to ScanForce

All Seasonings operates three warehouses, including a multiline production facility, and uses Sage to manage its operations. Several years ago, the business determined that directed picking, putaway, replenish, label printing, and license plating would streamline processes and increase efficiency.

The company integrated software with Sage to enable these functions. Unfortunately, however, the solution contained bugs that developers couldn’t resolve, even though the provider promised it would work “right out of the box.” In addition, because All Seasonings does not have an internal IT department, each issue resulted in tens of thousands of dollars in fees from their IT service provider or Sage consultant.

Other ScanForce Enhancements To Streamline Warehouse Processing

ScanForce offers numerous enhancements for Sage 100 / Sage 100cloud. Below are a few which fully integrate with their Warehouse Management offering.

Alias Unit of Measure – This Enhancement allows you to specify a unit of measure and a multiplier tying both to the first General Alias number in Item Maintenance. For example: Item ABC has an Alias Item Number of 123. The Unit of Measure may be CASE and the multiplier would be 24. Each time the user scans the Alias “123” ScanForce will automatically calculate that scan to equal 24 eaches.

Auto-Post – ScanForce AutoPost automatically updates, or posts, Purchase Order Receipt of Goods, Inventory Transactions, Bill of Material Production Entry, and Product Management transactions. This feature allows a real-time view of inventory levels. Know exactly what items you have available to sell and ship while eliminating the need to manually update these transactions back in Sage 100.

Dashboards – View realtime data related to Sales Order Status: Ready to Pick, Being Picked, Ready to Pack, and Shipped. Customize the data and view to suit your needs.

Container Receipt Management – Items arriving from overseas may take days or longer to arrive on the receiving dock. However, in many situations, you own the items the moment they leave the dock to being their journey to your location. It is important to account for these items in your inventory system, but not show them as available for sale. Utilizing the benefits within your Sage system provided by the use of Warehouse Codes and Bin Locations (requires the Sage selected DSD / ScanForce MultiBin Solution), ScanForce allows you to create a Purchase Order Receipt of Goods in Sage and ‘receive’ the items into a Warehouse or Bin designated for overseas items. ScanForce then allows you to validate the items and quantities based on the data on the initial Purchase Order. The items are automatically transferred from the Overseas Warehouse or Bin to the main locations in the warehouse.

Wave Receiving – This enhancement allows the grouping of Purchase Orders together giving the benefit of going item by item to record a receipt of more than one Purchase Order at a time.

Directed Picking – This feature is available in SF WMS Advanced and SF WMS Premium. Go paperless with SF Directed Picking. The mobile device displays items and locations to pick. The locations are sorted on the handheld affording the user the luxury of walking the warehouse one time to pick an order. More than one bin location may be used when DSD / ScanForce MultiBin is installed.

Pick to Pallet – Pick to Pallet offers a streamlined method to stage orders by pallet and then quickly, accurately, and efficiently ship the pallets.

Sales Order Picking – Sage does not allow for a status of an order to show as ‘picked’, but not invoiced. ScanForce provides this feature with SF SO Picking. This is available in SF WMS Advanced and SF WMS Premium. SF WMS Premium moves items out of the initial bin into a ‘staging’ bin location. The program writes back to SO Entry to change the allocated bin to the ‘staging’ bin.

Split Picking – Divide large Sales Orders into more than one picking sheet. Split the order by the number of lines, product line, or any of the category fields to allow more than one user to pick an order at the same time without the confusion of who is set to pick each line.

Wave Picking / Wave Shipping – Group Sales Orders together to pick (or ship) more than one at a time. There are two ways to create a wave – Sales Orders are selected on the mobile device and are “waved” or grouped together within the ScanForce mobile program. You can also create a wave within ScanForce’s Management Console using sophisticated selection criteria. Using SF Directed Picking the user is directed where to go in the warehouse and what to get. Items are automatically sorted by location.

Signature Capture at SO Shipping – This enhancement allows the capture of a signature in ScanForce Sales Order Shipping. The signature is saved as a file that is linked to the order history (invoice history) in Sage. The file can be tied to a printing form to allow the signature to display when the invoice is printed.

Make to Order – Production Management – Upon entering a Make to Order enabled item to a Sales Order, ScanForce’s Make to Order Automation enhancement allows you to create a Production Management Work Ticket directly from Sales Order Entry. ( Sage 100 2020+ )

Multi-Bin – Add the ability to capture WMS transactions including Multi-Bin locations with the handheld.

Pallet / License Plate Tracking – Adds the ability to track a unique ID for a group of items, typically a pallet. Receive, transfer and sell complete pallets.

Auto-Allocate by Case Pack – A new setting within Multi-Bin will allow to auto-allocate by Case Pack. When enabled, if the ordered quantity is greater than or equal to a Case Pack, it will direct the user to the Location Type that stores full cases of product (overstock). If the quantity ordered is less than a full case, then it will direct the user to the normal picking area first, and only to the full case locations if there is nothing else available.

SO Shipping / Delivery Signature Capture – Provides the ability to load orders onto a mobile device to validate remote delivery. Captures the customers’ signature approving the delivery. Data and signature import back to Sage 100 to create invoice. Signature can be added to printed docs and reports.

You must be logged in to post a comment.