Is your warehouse staff wasting time wandering the aisles of your warehouse picking items haphazardly? Could you increase productivity and speed up fulfillment if orders were picked in a more deliberate manner?

One solution to this is ScanForce Directed Picking for Sage 100, which is available for users of ScanForce WMS Advanced and Premium.

The concept of Directed Picking is to tell a user on their mobile device where to go within the warehouse to pick the goods and what to get. The device guides the user through the most efficient path based on item locations.

In this recording from ScanForce, join Steve Showalter as he walks you through the process.

This feature works with and without multi-bin. In the demo shown, Steve is referencing a bin location, so in a non multi-bin install this is going to look to the standard bin locations that are set up in Sage 100 inventory item maintenance.

How it works

This demonstration uses the DSD/ScanForce Multi-Bin which leverages the allocation methods back in the multi-bin solution, so it assigns a bin location based on a certain set of rules available within multi-bin.

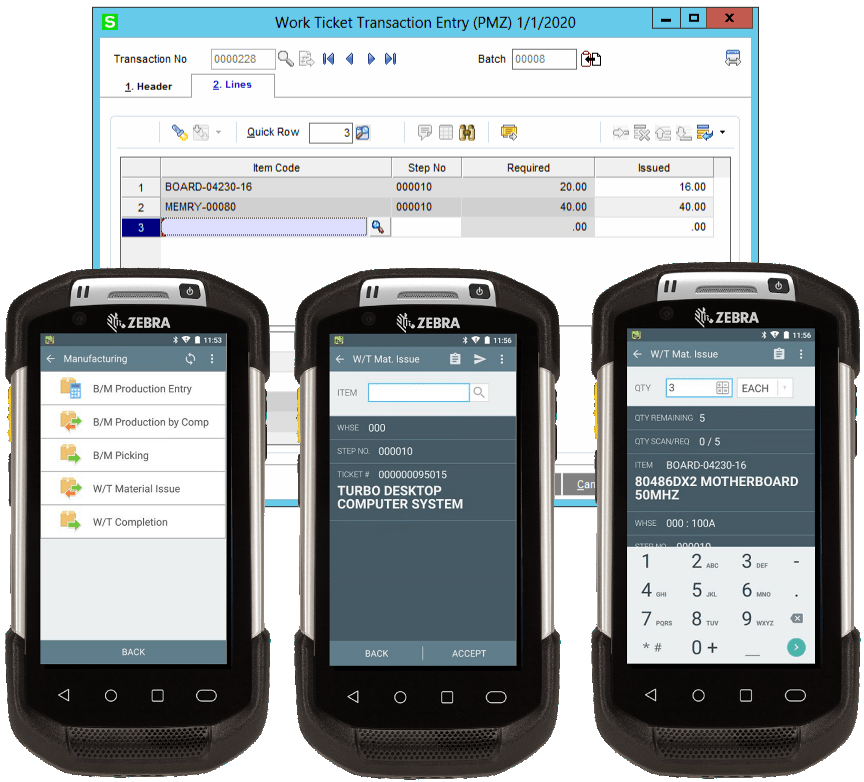

This allocation can occur automatically at several points. It can also be done manually back at the order level, so what you’ll see is simply an emulation of the mobile screen as is available on iOS and Android devices.

For this video, you’ll see the picking transaction, however the Directed Picking side carries through to the one-step Sage 100 Sales Order shipping if you’re not doing a staging of a Sales Order.

When the user launches Sage 100 Sales Order Picking on the mobile device, ScanForce will prompt for the Sage 100 Sales Order number. From here, the user can scan the order from a picking sheet, key it in, or do a lookup that connects in real-time to the Sage 100 accounting system displaying all available orders.

When the order has been selected, the device will connect up real-time and grab the information from Sage 100, placing it locally on the device. The user can then go stage this order with Multi-Bin by indicating a bin location. Sage can be set to default to a shipping bin, a staging bin, or any bin you’d like.

ScanForce Directed Picking takes over, and the display shows the user where to go and what to get – sorted by bin location as well.

Even though an item may be the first line on the sales order, ScanForce Directed Picking will direct the user to go to a different bin first to get a closer item because it’s sorting by bin locations. This means they’re not going all over the warehouse back and forth again, it’s a Directed Pick.

This also works with lot and serialized inventory type items. ScanForce Directed Picking will direct the user where to get these lot/serial numbers.

The ScanForce Directed Picking concept is to tell the person where to go using the most efficient route possible so they can quickly and easily pick or ship that Sage Sales Order.

Related reading: A Warehouse Nightmare

You must be logged in to post a comment.