Wave picking is the process of grouping together multiple-orders so they can be selected and staged for shipping by one person efficiently. The software guides warehouse workers through a route ensuring there is no doubling back to pick a stray item from across the warehouse floor.

Within native Sage 100 you’re able to print picking sheets. These are printed one per order and won’t take your bin locations into consideration when listing which items to pick first.

Using ScanForce Advanced WMS you’re able to directly read ( and write back ) your existing Sage data. This allows the WMS solution to route your warehouse personnel in the fastest way possible so there is less wasted time wandering a large warehouse.

Frequently you may want to record the location of an item in multiple places within your warehouse. When inventory is received it may be placed into an inspection area. When it’s ready for sale it may go into a “regular” bin location and when it’s been picked and is getting ready for shipping it may go into a separate shipping bin location.

These multiple bin locations are created within Sage 100 with the use of DSD/ScanForce Multi-Bin which natively integrates with all of your WMS modules ( Sales Order, Purchase Order, Inventory).

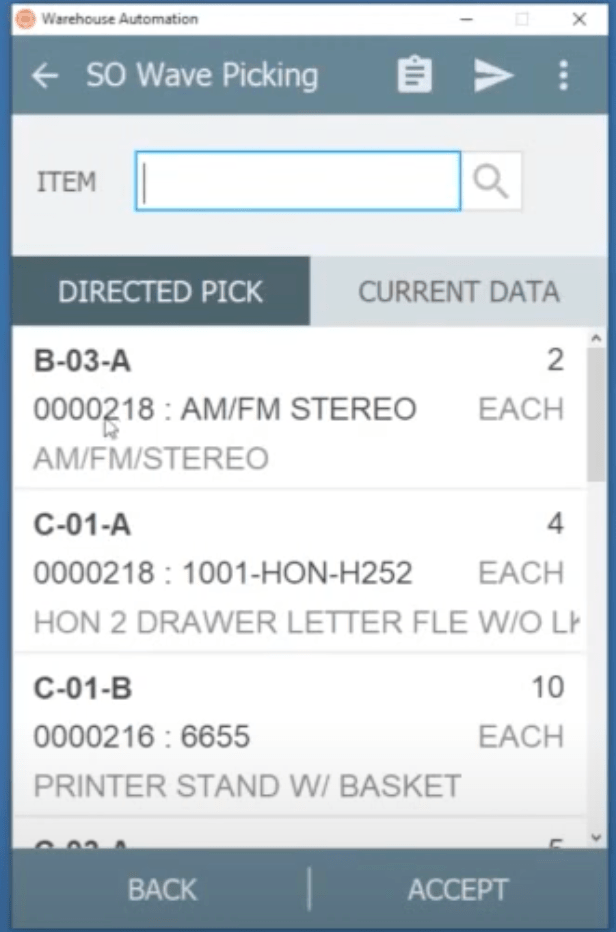

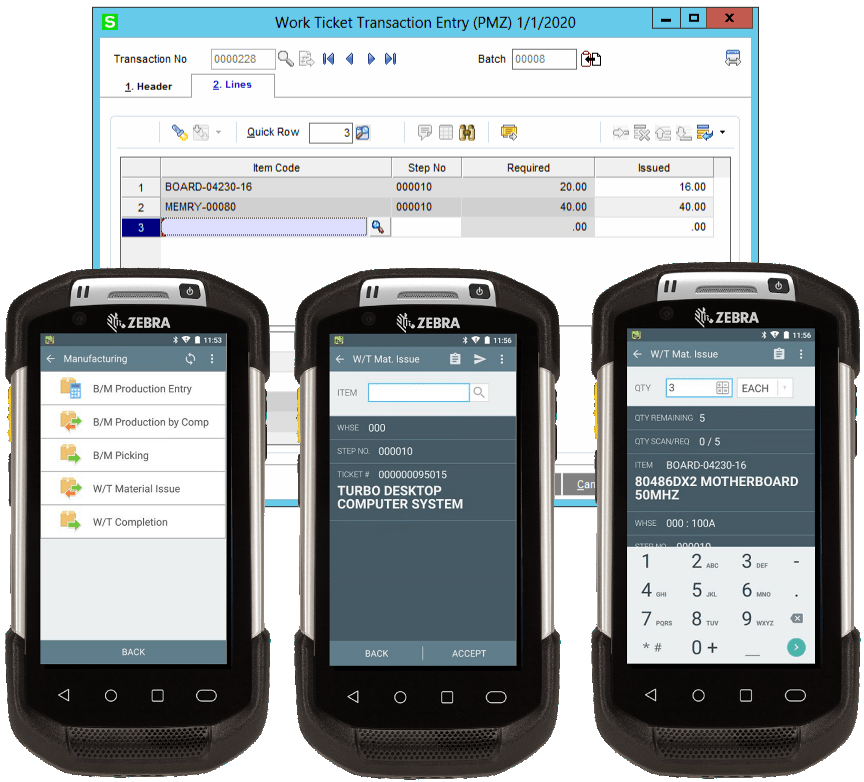

There are two steps to wave picking. One creates a wave in your Sage 100 system. The second creates the wave within the scanner itself.

Remember, wave picking is centered around the concept of grouping multiple sales orders together to pick all orders at one time walking the warehouse in the most efficient method possible.

In the video below, the first step is creating the wave in Sage 100 under the ScanForce module.

You can create a wave for a particular customer if you like. This can be handy when you ship multiple orders to one customer.

ScanForce also provides a tool for order selection. Select by a customer, ranges of customers, or ship date.

To pick the wave you’ll go on to the scanner and let it direct you through the warehouse as you pick the orders.

ScanForce picking works with DSD/ScanForce multi-bin. This allows you to specify a location where items are going to be staged until they are packed and shipped.

Typically you’ll use a shipping bin for segregating orders that are being staged.

If you’re on a forklift, for example, and you’re not able to actually scan a barcode you could tap on the screen (can be disabled forcing users to actually scan the items).

Once the order is picked, you’ll send it over to Sage 100. This does a few things. The first thing is to update the ScanForce dashboards in the order status now that it’s in the process of being picked and it’ll move over to packaged and then shipped. It also updates the bin locations at the order level, so you know that it’s now in shipping and staged for eventual shipping.

Another option is to create a wave from the actual handheld rather than in Sage 100. On the device, in wave picking you can select “Create Wave”. This is helpful if you receive a stack of orders that you need to ship for the day. Simply scan the orders into the wave, and you’re ready to go.

You must be logged in to post a comment.